HYDROSERVICE clamping discs were created to provide EASY and ECONOMIC clamping systems to ensure top reliability to machine manufacturers and engineers

From over 30 years Hydroservice is leader in the design and manufacturing of discs and clamping systems

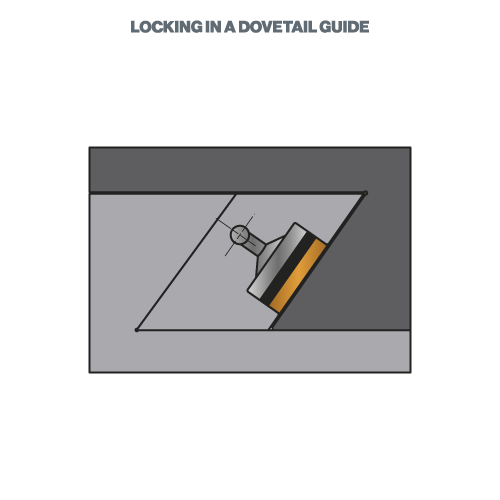

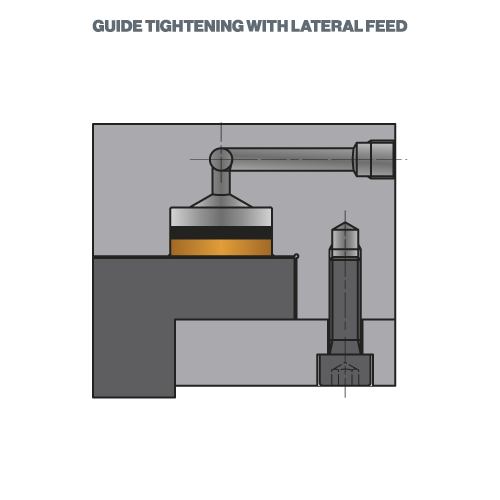

The seal on our disc is greatly oversized, therefore during assembly it is strongly preloaded obtaining high adherence in its seat.

Because of this, the Clamping element can be moved slightly in either direction without creating friction with the wall of the seat.

When the oil pressure will act on the seal first, this will be slightly compressed, eliminating frictions, and will move until the disc will be placed on the surface to be locked.

The seal will assume its final position.

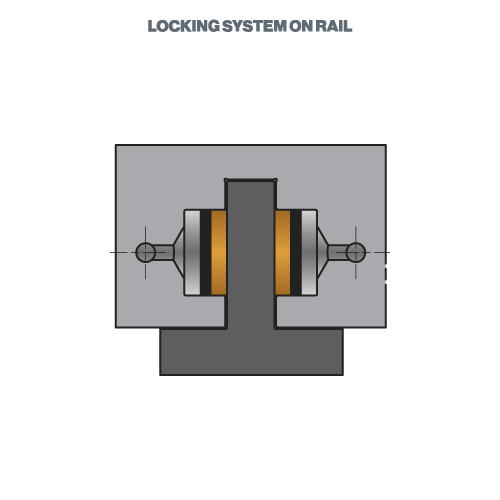

When unlocking the piece, simply release the pressure and the Clamping disc is spring returned of about 0.01 mm and comes away from the piece to be held.

It is important to point out that there is no friction during translation ensuring the longer life of the disc.

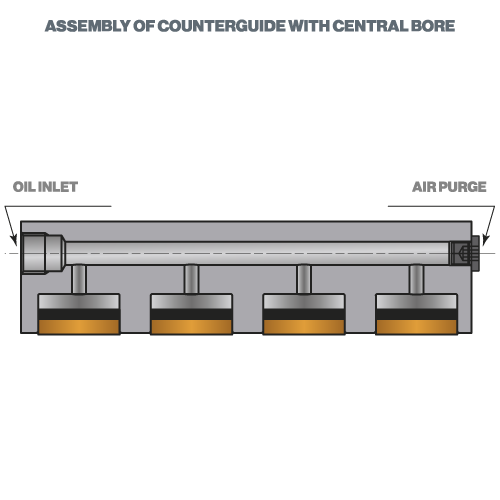

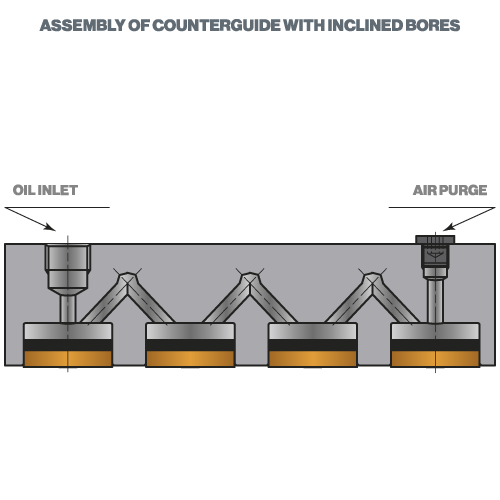

To ensure good working, avoid the formation of air bubbles in the pressurized oil circuit and purge any air in the circuit (if possible, create a vent hole in the most appropriate point). This feature, together with the frictionless nature of the seal, ensures the excellent expectancy and perfect efficiency of our disc.

e-shop

e-shop