The purpose of the Nitrogen Booster is to load the accumulators (individually or in the HPU) with nitrogen at preloading pressure, transferring it from the cylinder to the accumulator; the minimum pressure in the cylinder should be 20 bar.

The pre-loading pressure of nitrogen for the bag and piston accumulators must be checked periodically (about every 3-6 months) and corrected when necessary. Checks and corrections must be carried out without back-pressure on the oil side of the accumulator. It is necessary, therefore, to disable and drain the oil side, by means of the manual cut-off and decompression valve, before checking the accumulators.

After doing the above, a special valve must be connected to the nitrogen control and filling coupling on the head of the accumulator. This special component (the nitrogen control and filling device) is provided by the manufacturer of the accumulator.

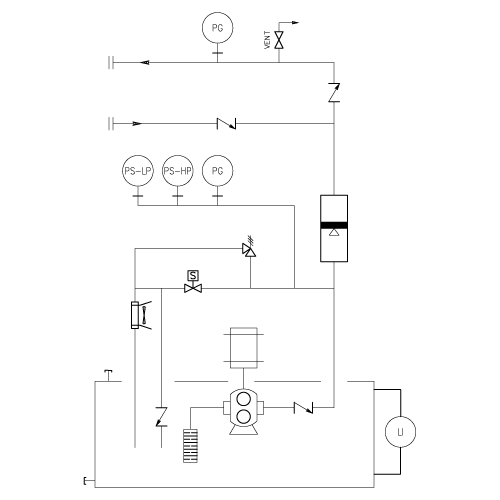

The Nitrogen Booster is connected to the electrical system, to the nitrogen cylinder by means of the "in PB" coupling, and with a hose to the accumulator to be filled (by means of the “out ACC” coupling).

The Nitrogen Booster is available in the Ex Model version.

e-shop

e-shop