Hydraulic manifolds: the regulating heart of modern hydraulic systems

An advanced technological solution for controlling the flow of fluids in a hydraulic system

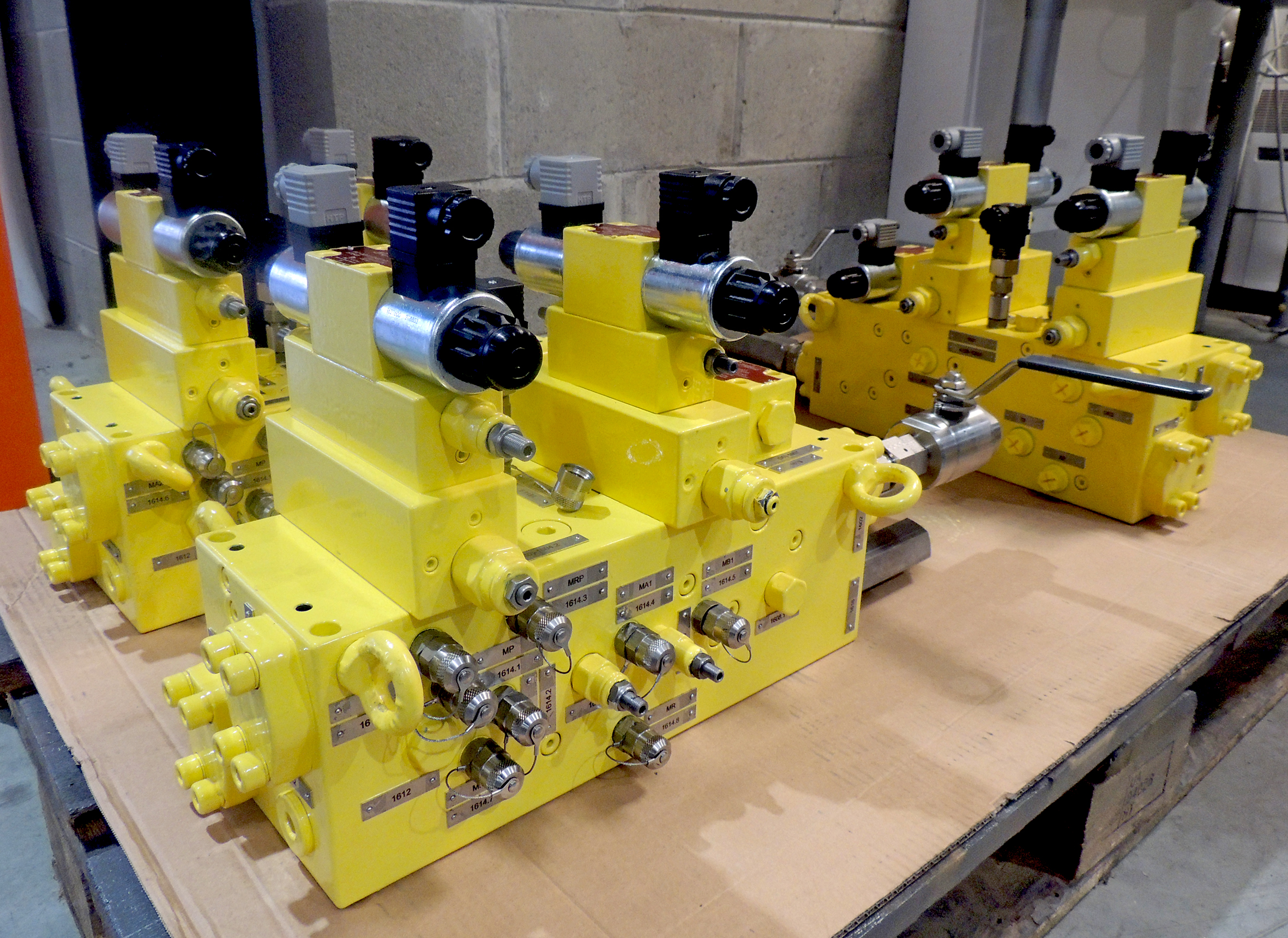

An essential component of modern hydraulic systems, hydraulic manifolds, also known as distributor blocks, are designed to direct and control the flow of fluid in a hydraulic system, ensuring it is properly regulated and distributed.

From the Second World War to multidisciplinary applications

Hydraulic manifolds were first used during World War II when mass production demands required quick and effective solutions for hydraulic flow control. Over the years, hydraulic manifolds have been used in a wide variety of applications including the automotive, aerospace, agriculture, construction industries and many more.

The power of high pressure flow management

Hydraulic manifolds offer many technological advantages over other flow control solutions. One of the main advantages is their ability to handle high pressure fluid flows. This makes them ideal for applications where a large amount of force is required, such as construction equipment, tractors and trucks.

In addition, hydraulic manifolds offer greater reliability than other flow control solutions, and because they are designed to be rugged and durable, they can operate reliably even in harsh environments such as dirt, dust or vibration.

Versatility and customization for each application

Hydraulic manifolds are available in a variety of shapes, sizes and configurations. However, most hydraulic manifolds consist of a solid block of metal that contains a system of channels, holes, and ports that allow fluid to enter and exit the system.

As for the materials, the blocks are usually made of metal alloys, such as stainless steel, titanium alloys, aluminum, cast iron, etc.

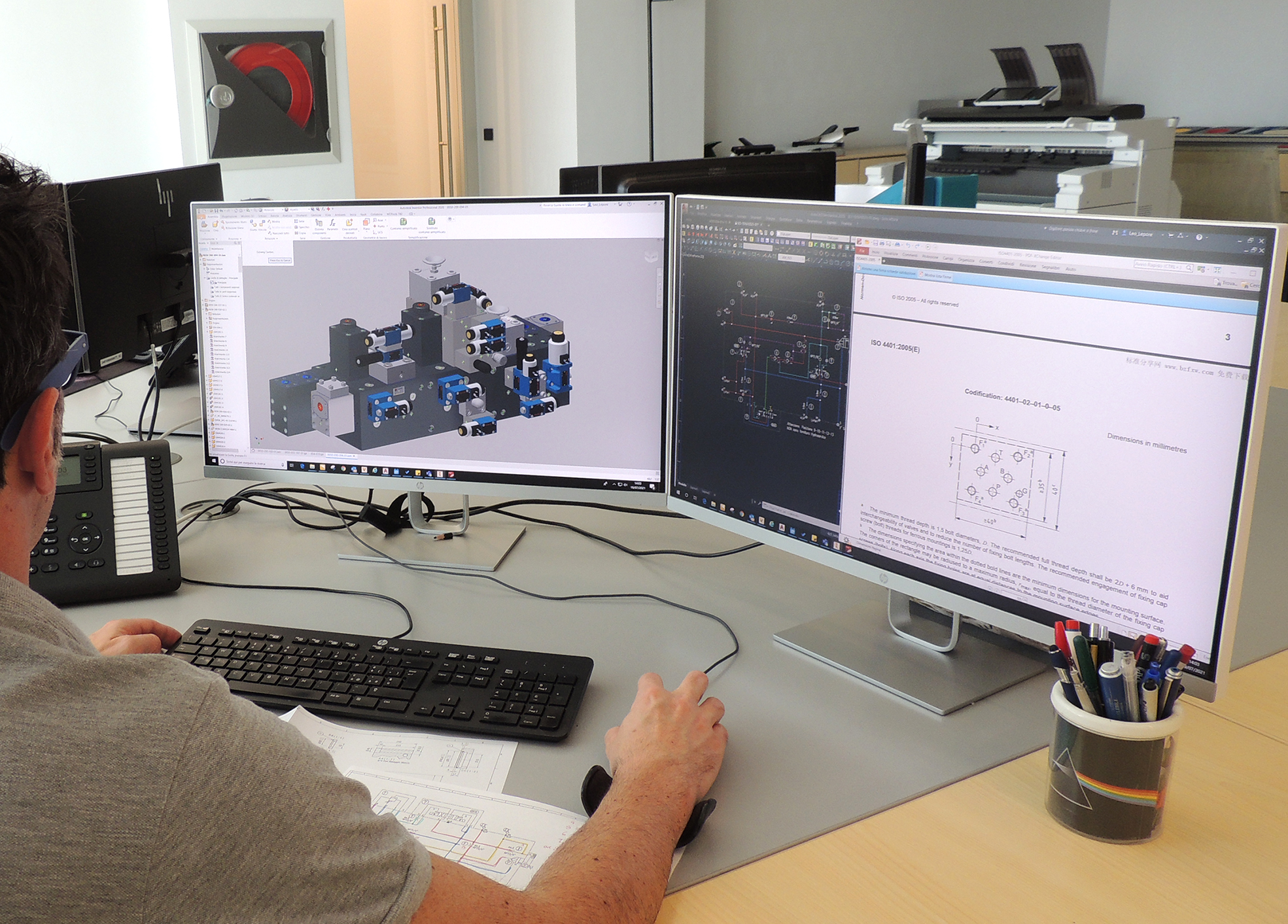

Hydraulic manifolds can be customized to meet the specific needs of each application. This means they can be designed to handle fluid flows at varying pressures and volumes, depending on the application.

The design of hydraulic manifolds must allow for the possibility of replacing components in emergency situations. In addition, manifold components must be easily accessible for maintenance and repair.

The most advanced solution for flow control in various industries

Hydraulic manifolds are an advanced technological solution for controlling the flow of fluids in a hydraulic system. Due to their ruggedness, reliability and ability to handle high pressure fluid flows, they have become a preferred solution for a wide range of applications in different industries including:

- Automotive industry: Hydraulic manifolds are used in braking systems, suspension systems and steering systems of vehicles.

- Aerospace Industry: Hydraulic manifolds are used in aircraft and spacecraft flight control systems.

- Marine industry: Hydraulic manifolds are used in rudder control systems, stabilization systems and mooring lifting systems.

- Construction industry: Hydraulic manifolds are used in construction machinery, such as excavators, cranes and concrete mixers.

- Oil industry: Hydraulic manifolds are used in pressure and flow control systems in oil wells.

The reference standards:

The design of the hydraulic manifolds must follow specific regulations in order to guarantee the safety and efficiency of the system. Here are some of the reference standards for the design of hydraulic manifolds:

- ISO 1219-1: This standard establishes the graphical conventions for hydraulic circuits, including manifolds. It describes how to graphically represent various circuit components, including manifolds, and also defines the symbologies used to represent circuit elements.

- ISO 4401: This standard defines specifications for directional control valves, which are often an integral part of hydraulic manifolds. It establishes the dimensions, mounting specifications, and functional characteristics of directional control valves.

- SAE Standards: SAE Standards J518 and J1453 set requirements for flanged joints and threaded connections.

- SAE J1926: This standard defines specifications for threaded connections used in hydraulic manifolds. It establishes the dimensions and tolerances for the threads of the connections, as well as the specifications for the sealants used to prevent leaks.

- EN 982: this standard defines the safety requirements for hydraulic circuit components, including manifolds. It establishes specifications for seals, relief valves and pressure resistance characteristics of components.